Introduction

Because this device is relatively simple problems are fairly easy to identify. Take the time, despite everything, to read the method to carry out a repair in good condition. Browse by following the two tutorials on functions and how it works. You will thus maximize the chances of success. In the first and the second stage, we will see the sources of breakdown located in the base, then in the third stage, we will consider those related to the iron itself.

-

-

One source of failure on this type of device is the pump which conveys the water contained in the tank to the iron. It's easy to tell if the pump is working. Just listen! The pump makes a noise, an easily audible hum. The noise is produced by the vibration of the core in the coil. See § operating principle.

-

How to test the pump: Before testing a pump, as before any repairs, ALWAYS check that the device is unplugged. The pump test is done by making a direct connection. We recommend extreme caution because this is a dangerous operation that requires protection. WARNING: DANGER

-

1- Disconnect the power supply to the pump. 2- Attach a pipe to the pump inlet and immerse it in a container of water. 3- Disconnect the pump outlet and insert a pipe with a container 4- Using an electrical cord, connect the pump terminals directly to the mains.

-

5- The pump should deliver the water. 6- If the pump does not start, the cause is either its cut coil or a clogged pump, a water leak, scale, intensive descaling with unsuitable doses of product.

-

-

-

-

The iron is controlled by a micro-controller (rep15). Here it is a PIC16F1820 In the event of an unexplained iron malfunction, it is likely that the PIC is to blame. In this case, there is unfortunately not much to do in the absence of the firmware loaded by the manufacturer.

-

Control of the heating resistor is entrusted to a relay (item 18). It is possible that this component is the cause if the resistor does not heat up. When the PIC sends the resistance heating information, the relay sticks. You may hear a slight "click" when this happens. If so, the command works fine.

-

If the relay clicks, the contact must be closed and the current must flow and supply the heating resistor. To ensure this, you must measure the voltage across the resistor.

-

If no voltage is measured, the relay is faulty (contact HS). If the voltage (220V~) is present, the resistance must be the cause.

-

Another common cause of failure can be the capacitor (rep17) This component is very present in small household appliances. This is a class X2 polyester capacitor. The value is close to 1 uF and the voltage > 220V. If in doubt, test it with a multimeter equipped with the capacitance function.

-

The control of the pump is entrusted to a thyristor (rep16) Here it is a BT168GW It can be blamed if the pump does not start. You must obviously start by testing the pump first (see step 1)

-

-

-

In this step we review the different organs present in the iron itself which can be the cause of a breakdown.

-

To check the condition of the resistance (rep11) simply measure its value with the ohmmeter. Knowing that the power announced by the manufacturer is 2400W, the resistance value must be close to 20 ohms. R =U²/P R=R=220²/2400=20 ohms

-

The probe (rep8) which captures the temperature of the sole is also checked by measuring its resistance. Here are the values measured at ambient and hot temperatures: t°=20°C > R= 300Ko - T°160°C > R= 3.5Ko

-

Concerning the klixon or safety thermostat (rep9) it is necessary to ensure the "continuity" of the circuit with the multimeter. There are several types of klixon (resettable or not). The one installed in the iron studied is automatically reset.

-

To learn more about safety probes and thermostats, see this page

-

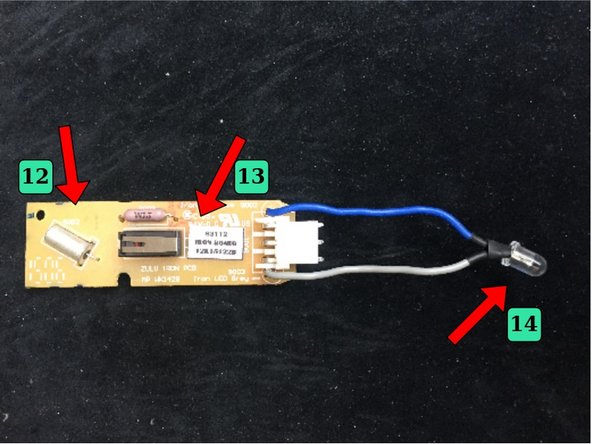

The push button (rep13) which controls the steam projection is tested continuously. The tilt switch (rep12) as well.

-

A source of problem can also come from the sheath which connects the iron to the fixed base. In this sheath passes the pipe which conducts the water from the tank to the iron as well as the electrical cables. This sheath is subject to twisting and can be damaged. To test it, you must measure the electrical continuity of the cables with a multimeter

-

To reassemble your device, follow the instructions in reverse order.

To reassemble your device, follow the instructions in reverse order.

Cancel: I did not complete this guide.

5 other people completed this guide.

Special thanks to these translators:

100%

These translators are helping us fix the world! Want to contribute?

Start translating ›